Viryasystech

02 May 2025

Viryasystech

Energy remains a driving force behind economic development, helping millions rise out of poverty and enhancing living standards for billions worldwide. However, a significant portion of the global population still lacks adequate access to energy and consumes far less than the global average. This combined challenge of promoting inclusive growth while addressing climate change creates a pressing need for industries to fundamentally rethink and reshape their energy consumption strategies.

At Viryasys Technologies, we believe that the industrial sector holds one of the most powerful levers in the fight against climate change, and that lever is energy transformation. With our solar and Battery Energy Storage Systems (BESS) offerings, we are helping industries reduce emissions, optimize energy use, and improve their bottom line in the process.

Industrial facilities are among the world’s largest consumers of energy and by extension, major contributors to greenhouse gas (GHG) emissions. Improving the energy efficiency of industrial processes is a critical strategy not only to reduce emissions, but to also boost profitability.

This is achieved by optimizing every stage of production from replacing obsolete equipment and installing high-efficiency motors to improving thermal insulation and integrating automated control systems. At Viryasys, we provide not just the hardware, but the intelligence and integration needed to make these systems work together seamlessly. Solar Energy: Promise Meets Policy Uncertainty

On-site solar power generation has emerged as one of the most promising pathways for the factories to reduce operational costs and emissions. Rooftop systems of 100 kW to multi-MW ground-mounted installations offer a direct, renewable alternative to fossil-fuel-based electricity.

However, while the technology is mature and proven, the implementation landscape remains patchy. Factors such as frequent shifts in net metering policies, state-wise regulatory discrepancies, and unclear grid integration norms often slow down decision-making and delay project execution. Despite these hurdles, many progressive factories are moving ahead, realizing that the long-term savings and sustainability benefits outweigh the transitional complexities.

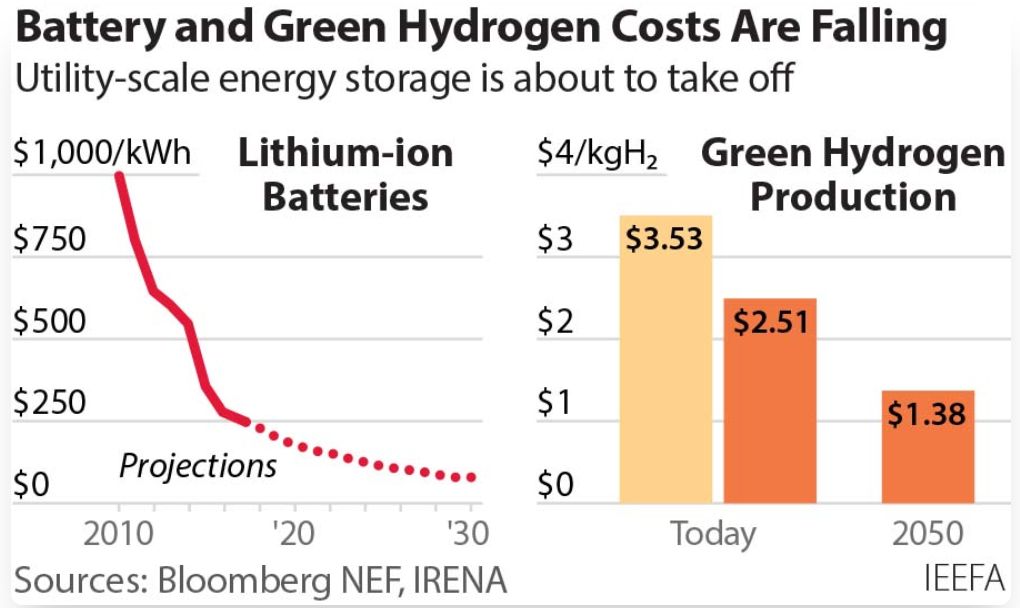

The ability to store solar power and use it during no sun shine hours is a game-changer for industrial operations, when grid power remains unreliable and tariff structures penalize peak-hour consumption. Pairing solar with BESS helps factories:

But the transition hasn’t been easy. For many businesses, initial capital cost, lack of clear policy incentives, and low awareness of lifecycle benefits delay adoption. Moreover, the lack of standardized subsidy mechanisms or depreciation benefits across states adds further ambiguity to investment decisions.

That said, industrial leaders are starting to recognize BESS not just as a backup system, but as an energy optimization tool. With AI-powered platforms, BESS can now predict demand spikes, enable peak load shaving, and facilitate energy arbitrage — turning stored power into strategic cost savings.

Many factories are ready to transform, but policy clarity, fiscal incentives, and execution support remain critical enablers. The technologies are available. The intent exists. What’s needed now is a favourable consistent, industry-aligned policy environment that gives confidence to invest, innovate, and decarbonize at scale.

Until then, the gap between ambition and adoption will remain — but for those who act early, the first-mover advantage in cost, compliance, and competitiveness will be real and measurable.

A friend of ours with deep roots in industrial operations once summed it up perfectly:

“ For every ₹1 crore of investment, there must be a minimum saving of ₹1 per kWh of electricity consumed — over a viable consumption volume.”

A grounded benchmark that simplifies clean energy ROI assessment for industries.

A calculation that illustrates the financial viability of transitioning to Solar + BESS in the context of Indian industrial energy consumption, aligned with your rule of thumb.

Investment Amount

Project Type

System Size (approx.)

Average Daily Generation

Annual Energy Generation

Project Lifetime Considered

Total Energy Generated (10 years)

Minimum Required Saving per kWh

Total Expected Saving Over 10 Years

Current Grid/DG Power Cost (approx.)

Cost After Solar + BESS Integration

Target Industrial Consumption Volume

Applicable Industries

₹1 Crore

Rooftop Solar + BESS

100 kW Solar + Battery Storage

~2,740 kWh/day

~10,00,000 kWh/year

10 years

~1,00,00,000 kWh (1 crore units)

₹1

₹1 crore

₹9–10 per kWh

₹7–8 per kWh

~10,00,000 kWh/year (≈83,000 kWh/month)

Medium to large-scale factories, process industries, commercial units

A ₹1 crore investment in clean energy assets must serve industries consuming 10 lakh kWh per year (~83,000 units/month).

These are typical volumes for mid-sized manufacturing units, process industries, or large commercial establishments.

If the current grid cost (including peak charges and DG backup) is around ₹9–10/kWh, shifting to solar + BESS can bring that down to ₹7–8/kWh or lower, meeting the saving target.

The return improves further with incentives, accelerated depreciation, and carbon credits, depending on the state or central policies.

Many industries delay decarbonization, fearing high upfront costs. But here’s what’s often missed:

What appears as a cost today is actually a competitive advantage in the making.

Sustainability is no longer just an internal KPI. Many international buyers now assess the carbon footprint of their suppliers. By decarbonizing energy use, industries can unlock upstream export opportunities, improve ESG ratings, and qualify for preferred vendor status with global brands and government buyers.

The case for BESS and solar is no longer a debate between sustainability and profitability. It’s a solution that offers both: clean energy today, competitive strength tomorrow.

As industries rethink their energy choices, it’s time to replace the outdated, polluting DGs and inefficient systems with smarter, cleaner, and more resilient technologies. Viryasys Technologies is here to help make that transition practical, profitable, and powerful.

Our projects are more than just turnkey; they are the embodiment of cutting-edge technology and unwavering commitment. We commit to the asset owners a long-term, uninterrupted, and reliable source of renewable energy, ensuring a substantial return on your investment.

As the world races toward a cleaner, greener future, the spotlight is on how we store energy sustainably. Solar and wind power are leading the charge, but there's one big challenge: they don't generate electricity all the time.

Read More

In industrial corridors across the country, a familiar hum persists, the sound of diesel generators (DGs) kicking in during peak hours or outages.

Read More

In the world of high-temperature insulation, the choice of materials has a direct impact on operational efficiency, furnace longevity, and product quality.

Read More