AdiNal Group

02 May 2025

Viryasystech

In the world of high-temperature insulation, the choice of materials has a direct impact on operational efficiency, furnace longevity, and product quality. While ceramic fibre (RCF) insulation has long been the standard, there is a growing shift toward polycrystalline wool (PCW) blankets—and for good reason. Steel plants and other high-temperature process industries are beginning to realise that PCW offers a host of benefits that far outweigh its higher initial cost.

One of the most significant advantages of PCW blankets is their higher alumina content, which translates into enhanced thermal efficiency. This means that at the same insulation thickness, PCW offers better heat retention, reducing energy consumption. Improved thermal performance also minimizes wear and tear on the furnace’s metal structure—helping to extend equipment life and reduce maintenance costs.

Unlike RCF, which tends to degrade and require frequent replacement, PCW blankets offer remarkable durability, typically lasting four to five times longer in use. Their superior structural integrity and low shot content significantly reduce dusting, ensuring cleaner operations and less contamination of products. This also means fewer shutdowns for maintenance and replacement, improving operational uptime.

RCF materials can shrink significantly at extreme temperatures, often leading to hot spots on furnace walls. PCW blankets, on the other hand, exhibit less than 2% shrinkage even at 1600°C, maintaining their insulation performance and preventing the formation of these heat leaks. This makes PCW an excellent choice for more demanding thermal environments.

Furnaces with high gas flow or abrasive environments, particularly around burner areas, often see accelerated insulation degradation. PCW’s enhanced erosion resistance allows for installations at lower densities, helping to cut costs without sacrificing performance. This also makes PCW more versatile, capable of insulating even the most challenging and high-wear areas.

For operations that involve reducing atmospheres or exposure to alkaline or acidic chemical attack, PCW’s high chemical purity provides a robust defense. This superior resistance helps ensure insulation longevity and integrity where RCF would otherwise begin to break down.

All these advantages point to a single outcome: longer-lasting, more efficient furnace operation. While the upfront investment in PCW may be higher, the long-term savings in energy, maintenance, downtime, and replacement materials make it a far more cost-effective solution. In today’s competitive and sustainability- driven steel industry, these benefits are not just nice to have—they're essential.

If you’re exploring ways to optimise your furnace performance and reduce operating costs, transitioning to PCW insulation could be the key. We’d be happy to answer your questions, discuss specific applications, or even provide trial materials to help you see the difference firsthand.

Let’s talk about how PCW can help you raise the bar on performance and efficiency.

Our projects are more than just turnkey; they are the embodiment of cutting-edge technology and unwavering commitment. We commit to the asset owners a long-term, uninterrupted, and reliable source of renewable energy, ensuring a substantial return on your investment.

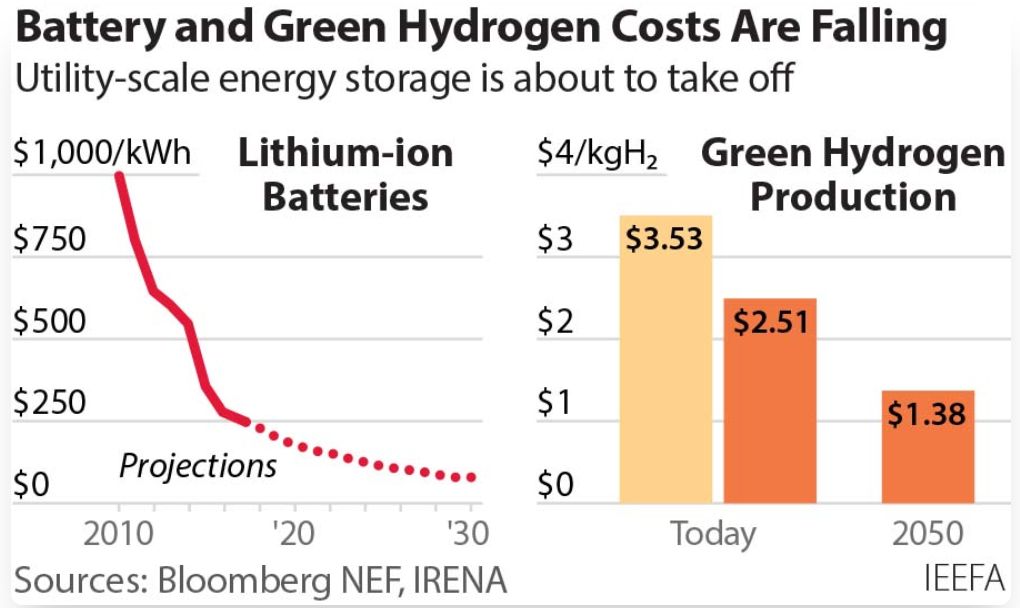

As the world races toward a cleaner, greener future, the spotlight is on how we store energy sustainably.Solar and wind power are leading the charge, but there's one big challenge: they don't generate electricity all the time.

Read More

Energy remains a driving force behind economic development, helping millions rise out of poverty and enhancing living standards for billions worldwide.

Read More

In industrial corridors across the country, a familiar hum persists, the sound of diesel generators (DGs) kicking in during peak hours or outages.

Read More